Atherm is proud to launch the Supratherm Dual 75, a brand-new immersion heater developed by our innovation lab. We are thrilled to present this game-changer for die-casting furnaces during Euroguss 2024.

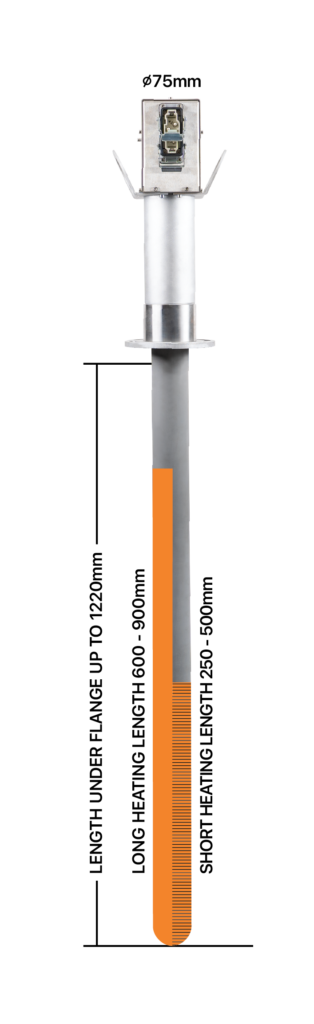

This unique 2-in-1 electrical immersion heater, with two independent heating lengths, is designed for two-tier operations, to meet the needs of our most demanding customers: Gigafactories. Its power ratings range from 2 to 12 kW in air, and from 14 to 27 kW in aluminum*. Like all Atherm immersion heaters, it is customizable to provide a specific target power rating, by varying the lengths of the long and the short heating units.

Supratherm Dual 75 can be used in two different ways.

To preheat furnaces

To preheat furnaces

The long heating unit is used in the empty furnace. Thanks to its lower power ratings, it first dries, then heats the refractory material, along with the atmosphere, in preparation for the filling phase.

The long heating unit can also be used during the filling phase, to heat the partially aluminum-filled furnace. This feature is a true game-changer for furnaces.

The short heating unit takes over as soon as it is completely immersed in liquid aluminum. It then delivers the maximum possible power to the molten metal – from 14 to 27 kW, depending on its length – to allow temperature holding and melting in the same way as Atherm’s other Supratherm heaters.- To improve furnace-filling flexibility

The long heating unit is used when the molten metal levels are high, while the short unit delivers its full potential with lower metal levels.

By changing the heating length, the Supratherm Dual 75 better tolerates variations in bath-depth, increasing the time between filling baths.

The Supratherm Dual 75 is very simple to use. It is equipped with two independent power plugs and heating systems, consequently everything operates as if you had two classical Supratherm immersion heaters that can be switched on or off depending on the bath level.

Meet us at Euroguss 2024 from January 16 to 18, stand 8-303 in hall 8. We would love to show you this addition to the range of our immersion heaters and to walk you through some of the outstanding use cases from our 30+ years of experience with thermal management of light-metals.

* Example given for aluminum at 700°C.