Today, on October 16, at Galvatech 2023, in Seoul (Korea), ArcelorMittal presented the results of their tests of Atherm’s immersion heaters (IH) in their hot dip galvanizing pots.

We had a chat with the author of this work, Matthieu Didier, senior scientist for Global Research and Development at Maizières (France), to bring you his first-hand feedback. A poster summarizing the essentials can be viewed at Atherm’s booth during Galvatech 2023.

ArcelorMittal on its recent trial of Atherm’s immersion heaters

At Galvatech 2023, in Seoul (Korea), ArcelorMittal is presenting a test of Atherm’s immersion heaters (IH) in hot dip galvanizing pots. What was the driving force behind this work? What are the conclusions? We put these questions to the author, Matthieu Didier, senior scientist for Global Research and Development at Maizières-lès-Metz (France).

ArcelorMittal’s Global R&D decided to test Atherm’s immersion heaters in 2019. What triggered that decision?

Today, ArcelorMittal is mainly using induction furnaces for galvanisation of flat products steel. When immersion heaters technology for these applications was mentioned during a course in 2019, our department undertook some research and identified three very interesting aspects. First: IH have very high heating yields, without CO2 emissions during production. Second: They are simple and flexible, from implementation to maintenance. Finally: The technology has been extensively tested for aluminium, and numerous industrial references are available.

Given the low technological risk, we decided to test them in our conditions for two applications. The first represented a short-term objective: to use IH as a complementary heating system, adding power to our baths. The second represented a longer-term goal: to develop pots entirely heated by IH, thus a complete change relative to current practice.

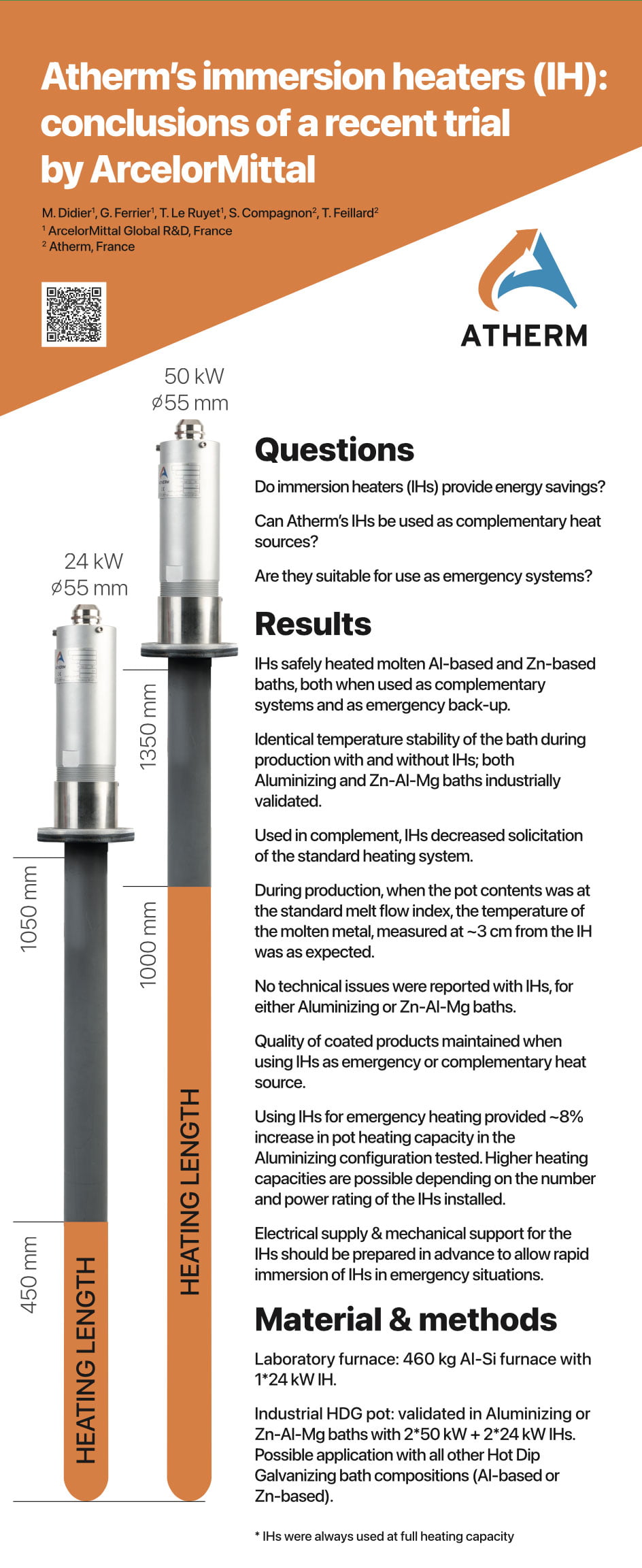

Through our industrial partners, we identified Atherm as an established producer. We started our tests in 2021 with standard 24-kW IH, first for successful laboratory tests; we then moved on to industrial furnaces. These preliminary tests were then complemented with tests of 50-kW IH, as our production lines required greater power.

Your presentation at Galvatech summarises your findings from this study. What was the outcome?

We are happy with the overall results. The tests confirmed that IH could be used to add heating power and to reduce energy consumption. The IH are simple to implement and use, as well as being truly flexible. We tested them on five different lines, and in several baths: aluminium and zinc alloys. No insurmountable obstacles were encountered.

Importantly: adding IH to existing furnaces never had a negative impact on production or the quality of the coils produced.

From our initial analysis, we expected low usage constraints – installation in the baths, encumbrance, maintenance, cleaning – and this was confirmed.

What remains to be determined now is how long the units last in use. At this stage – after two years of usage of our equipment – we have not had any losses. We are keen to find out more about their longevity*.

The primary objective of our tests – to provide greater heating power for crucibles, for example to avoid the need to design new crucibles for sites developing new products requiring higher pot heating capacity – has been achieved. By adding a few IH to the bath, the adaptation comes at a lower cost.

The IH were also used when there was a problem with some inductors on specific lines. If immediate maintenance is not available, IH can be installed to pursue the scheduled production. This use as back-up was consistently highly appreciated on our sites, as it takes the burden off our collaborators and the existing equipment. Finally, given the flexibility of IH, we also used them for special operations: to prepare a new bath, to provide additional heating allowing us to schedule maintenance or undertake longer-duration maintenance.

Given these promising results, are you planning to adapt your practice?

We have already retained the idea that IH can be used in complement to our current heating method and for technical assistance, even if we are still studying their applications. In the longer term, we are considering crucibles heated only by IH.

As we all know, there is an environmental pressure: ArcelorMittal targets to produce carbon-neutral steel with net-zero CO2 emissions in 2050. Atherm’s technology does not produce CO2 itself, therefore it is among the prime targets. It also meets the second level of requirements, as it uses carbon-free energy, in the form of electricity. Finally, the energy yield of the process exceeds 95%, so we will reduce our energy consumption compared to induction heating, and we will win all round.

*Clarification from Atherm: In our experience, experimental usage conditions are more demanding for IH than continuous use on a production line. Atherm has several clients where their IH have an average lifespan of more than 5 years in standard production conditions.